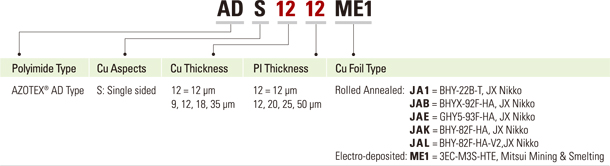

AD Series - Single Sided Flexible Copper Clad Laminates (FCCL)

.jpg)

Scrolling the table to read more

Scrolling the table to read more

| Item | Unit |

ADS1212ME1

|

ADS1220ME1

|

Test Method |

|---|---|---|---|---|

|

Coefficient of Thermal Expansion |

ppm |

18±2

|

18±2

|

TMA |

|

Glass Transition Temperature |

℃ |

> 350

|

> 350

|

TMA |

|

Flame Resistance |

- |

VTM-0

|

VTM-0

|

UL 94 |

|

Dimensional Stability (MD) |

% |

within ±

0.08 |

within ±

0.08 |

IPC-TM-650, 2.2.4 |

|

Dimensional Stability (TD) |

% |

within ±

0.08 |

within ±

0.08 |

IPC-TM-650, 2.2.4 |

|

Tensile Strength |

MPa |

> 230

|

> 230

|

IPC-TM-650, 2.4.19 |

|

Elongation |

% |

> 40

|

> 40

|

IPC-TM-650, 2.4.19 |

|

Peeling Strength |

kN/m |

> 0.8

|

> 0.8

|

JIS C-5016 |

|

Flexural Endurance (MIT) (MD) |

Cycles |

> 5,000

|

> 4,000

|

JIS C-6471 |

|

Flexural Endurance (MIT) (TD) |

Cycles |

> 5,000

|

> 4,000

|

L/S=1.0 mm, R=0.8 mm |

|

Soldering Resistance |

- |

PASS

|

PASS

|

340℃, 10 sec |

|

Surface Resistance |

Ω |

>1014

|

>1014

|

IPC-TM-650, 2.5.17 |

|

Flame Resistance |

Ω-cm |

>1014

|

>1014

|

IPC-TM-650, 2.5.17 |

|

Dielectric Strength |

kV/mil |

> 5

|

> 5

|

IPC-TM-650, 2.5.6.2 |

| Item | Unit |

ADS1225ME1

|

ADS1850ME1

|

Test Method |

|---|---|---|---|---|

|

Coefficient of Thermal Expansion |

ppm |

18±2

|

18±2

|

TMA |

|

Glass Transition Temperature |

℃ |

> 350

|

> 350

|

TMA |

|

Flame Resistance |

- |

V-0

|

V-0

|

UL 94 |

|

Dimensional Stability (MD) |

% |

within ±

0.08 |

within ±

0.08 |

IPC-TM-650, 2.2.4 |

|

Dimensional Stability (TD) |

% |

within ±

0.08 |

within ±

0.08 |

IPC-TM-650, 2.2.4 |

|

Tensile Strength |

MPa |

> 230

|

> 230

|

IPC-TM-650, 2.4.19 |

|

Elongation |

% |

> 40

|

> 40

|

IPC-TM-650, 2.4.19 |

|

Peeling Strength |

kN/m |

> 0.8

|

> 0.7

|

JIS C-5016 |

|

Flexural Endurance (MIT) (MD) |

Cycles |

> 4,000

|

> 100

|

JIS C-6471 |

|

Flexural Endurance (MIT) (TD) |

Cycles |

> 4,000

|

> 100

|

L/S=1.0 mm, R=0.8 mm |

|

Soldering Resistance |

- |

PASS

|

PASS

|

340℃, 10 sec |

|

Surface Resistance |

Ω |

>1014

|

>1014

|

IPC-TM-650, 2.5.17 |

|

Flame Resistance |

Ω-cm |

>1014

|

>1014

|

IPC-TM-650, 2.5.17 |

|

Dielectric Strength |

kV/mil |

> 5

|

> 5

|

IPC-TM-650, 2.5.6.2 |

| Item | Unit |

ADS1212JA1

|

ADS1812JA1

|

Test Method |

|---|---|---|---|---|

|

Coefficient of Thermal Expansion |

ppm |

18±2

|

18±2

|

TMA |

|

Glass Transition Temperature |

℃ |

> 350

|

> 350

|

TMA |

|

Flame Resistance |

- |

VTM-0

|

VTM-0

|

UL 94 |

|

Dimensional Stability (MD) |

% |

within ±

0.08 |

within ±

0.1 |

IPC-TM-650, 2.2.4 |

|

Dimensional Stability (TD) |

% |

within ±

0.08 |

within ±

0.1 |

IPC-TM-650, 2.2.4 |

|

Tensile Strength |

MPa |

> 230

|

> 230

|

IPC-TM-650, 2.4.19 |

|

Elongation |

% |

> 40

|

> 40

|

IPC-TM-650, 2.4.19 |

|

Peeling Strength |

kN/m |

> 0.7

|

> 0.7

|

JIS C-5016 |

|

Flexural Endurance (MIT) (MD) |

Cycles |

> 8,000

|

> 5,000

|

JIS C-6471 |

|

Flexural Endurance (MIT) (TD) |

Cycles |

> 8,000

|

> 5,000

|

L/S=1.0 mm, R=0.8 mm |

|

Soldering Resistance |

- |

PASS

|

PASS

|

340℃, 10 sec |

|

Surface Resistance |

Ω |

>1014

|

>1014

|

IPC-TM-650, 2.5.17 |

|

Flame Resistance |

Ω-cm |

>1014

|

>1014

|

IPC-TM-650, 2.5.17 |

|

Dielectric Strength |

kV/mil |

> 5

|

> 5

|

IPC-TM-650, 2.5.6.2 |

| Item | Unit |

ADS1825JA1

|

ADS1850JA1

|

Test Method |

|---|---|---|---|---|

|

Coefficient of Thermal Expansion |

ppm |

18±2

|

18±2

|

TMA |

|

Glass Transition Temperature |

℃ |

> 350

|

> 350

|

TMA |

|

Flame Resistance |

- |

V-0

|

V-0

|

UL 94 |

|

Dimensional Stability (MD) |

% |

within ±

0.05 |

within ±

0.05 |

IPC-TM-650, 2.2.4 |

|

Dimensional Stability (TD) |

% |

within ±

0.05 |

within ±

0.05 |

IPC-TM-650, 2.2.4 |

|

Tensile Strength |

MPa |

> 230

|

> 230

|

IPC-TM-650, 2.4.19 |

|

Elongation |

% |

> 40

|

> 40

|

IPC-TM-650, 2.4.19 |

|

Peeling Strength |

kN/m |

> 0.7

|

> 0.7

|

JIS C-5016 |

|

Flexural Endurance (MIT) (MD) |

Cycles |

> 2,000

|

> 100

|

JIS C-6471 |

|

Flexural Endurance (MIT) (TD) |

Cycles |

> 2,000

|

> 100

|

L/S=1.0 mm, R=0.8 mm |

|

Soldering Resistance |

- |

PASS

|

PASS

|

340℃, 10 sec |

|

Surface Resistance |

Ω |

>1014

|

>1014

|

IPC-TM-650, 2.5.17 |

|

Flame Resistance |

Ω-cm |

>1014

|

>1014

|

IPC-TM-650, 2.5.17 |

|

Dielectric Strength |

kV/mil |

> 5

|

> 5

|

IPC-TM-650, 2.5.6.2 |

| Item | Unit |

ADS1225JAE

|

ADS1850JAE

|

Test Method |

|---|---|---|---|---|

|

Coefficient of Thermal Expansion |

ppm |

20±4

|

20±4

|

TMA |

|

Glass Transition Temperature |

℃ |

> 350

|

> 350

|

TMA |

|

Flame Resistance |

- |

V-0

|

V-0

|

UL 94 |

|

Dimensional Stability (MD) |

% |

within ±

0.08 |

within ±

0.08 |

IPC-TM-650, 2.2.4 |

|

Dimensional Stability (TD) |

% |

within ±

0.08 |

within ±

0.08 |

IPC-TM-650, 2.2.4 |

|

Tensile Strength |

MPa |

> 230

|

> 230

|

IPC-TM-650, 2.4.19 |

|

Elongation |

% |

> 40

|

> 40

|

IPC-TM-650, 2.4.19 |

|

Peeling Strength |

kN/m |

> 0.7

|

> 0.7

|

JIS C-5016 |

|

Flexural Endurance (MIT) (MD) |

Cycles |

> 5,000

|

> 200

|

JIS C-6471 |

|

Flexural Endurance (MIT) (TD) |

Cycles |

> 5,000

|

> 200

|

L/S=1.0 mm, R=0.8 mm |

|

Soldering Resistance |

- |

PASS

|

PASS

|

340℃, 10 sec |

|

Surface Resistance |

Ω |

>1014

|

>1014

|

IPC-TM-650, 2.5.17 |

|

Flame Resistance |

Ω-cm |

>1014

|

>1014

|

IPC-TM-650, 2.5.17 |

|

Dielectric Strength |

kV/mil |

> 5

|

> 5

|

IPC-TM-650, 2.5.6.2 |

| Item | Unit |

ADS1225JAK

|

ADS1850JAB

|

Test Method |

|---|---|---|---|---|

|

Coefficient of Thermal Expansion |

ppm |

18±2

|

18±2

|

TMA |

|

Glass Transition Temperature |

℃ |

> 350

|

> 350

|

TMA |

|

Flame Resistance |

- |

V-0

|

V-0

|

UL 94 |

|

Dimensional Stability (MD) |

% |

within ±

0.05 |

within ±

0.05 |

IPC-TM-650, 2.2.4 |

|

Dimensional Stability (TD) |

% |

within ±

0.05 |

within ±

0.05 |

IPC-TM-650, 2.2.4 |

|

Tensile Strength |

MPa |

> 230

|

> 230

|

IPC-TM-650, 2.4.19 |

|

Elongation |

% |

> 40

|

> 40

|

IPC-TM-650, 2.4.19 |

|

Peeling Strength |

kN/m |

> 0.7

|

> 0.8

|

JIS C-5016 |

|

Flexural Endurance (MIT) (MD) |

Cycles |

> 4,000

|

> 3,000

|

JIS C-6471 |

|

Flexural Endurance (MIT) (TD) |

Cycles |

> 4,000

|

> 3,000

|

L/S=1.0 mm, R=0.8 mm |

|

Soldering Resistance |

- |

PASS

|

PASS

|

340℃, 10 sec |

|

Surface Resistance |

Ω |

>1014

|

>1014

|

IPC-TM-650, 2.5.17 |

|

Flame Resistance |

Ω-cm |

>1014

|

>1014

|

IPC-TM-650, 2.5.17 |

|

Dielectric Strength |

kV/mil |

> 5

|

> 5

|

IPC-TM-650, 2.5.6.2 |

| Item | Unit |

ADS1225JAL

|

Test Method |

|---|---|---|---|

|

Coefficient of Thermal Expansion |

ppm |

18±2

|

TMA |

|

Glass Transition Temperature |

℃ |

> 350

|

TMA |

|

Flame Resistance |

- |

V-0

|

UL 94 |

|

Dimensional Stability (MD) |

% |

within ±

0.05 |

IPC-TM-650, 2.2.4 |

|

Dimensional Stability (TD) |

% |

within ±

0.05 |

IPC-TM-650, 2.2.4 |

|

Tensile Strength |

MPa |

> 230

|

IPC-TM-650, 2.4.19 |

|

Elongation |

% |

> 40

|

IPC-TM-650, 2.4.19 |

|

Peeling Strength |

kN/m |

> 0.7

|

JIS C-5016 |

|

Flexural Endurance (MIT) (MD) |

Cycles |

> 4,000

|

JIS C-6471 |

|

Flexural Endurance (MIT) (TD) |

Cycles |

> 4,000

|

L/S=1.0 mm, R=0.8 mm |

|

Soldering Resistance |

- |

PASS

|

340℃, 10 sec |

|

Surface Resistance |

Ω |

>1014

|

IPC-TM-650, 2.5.17 |

|

Flame Resistance |

Ω-cm |

>1014

|

IPC-TM-650, 2.5.17 |

|

Dielectric Strength |

kV/mil |

> 5

|

IPC-TM-650, 2.5.6.2 |

|

||

| Configurations | ||

|

|

||||||

|